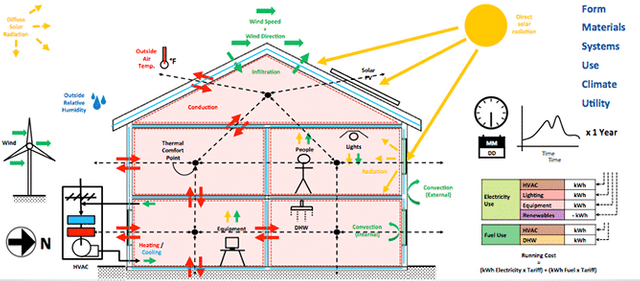

CERLOS — is an eco-friendly, sustainable, high-performance building material that is fire, mold, rot and insect resistant. CERLOS was born from our desire to solve four global issues:

(1) agricultural/forestry waste,

(2) energy shortfall,

(3) hazardous building materials, and

(4) environmentally unsustainable materials. As a result, it will improve the quality of life physically, financially and environmentally.

CERLOS is holding a fundraiser via IEO so we can build a manufacturing facility for commercial production of CERLOS products. We welcome investment opportunities, strategic partnerships and certified representatives to join us.

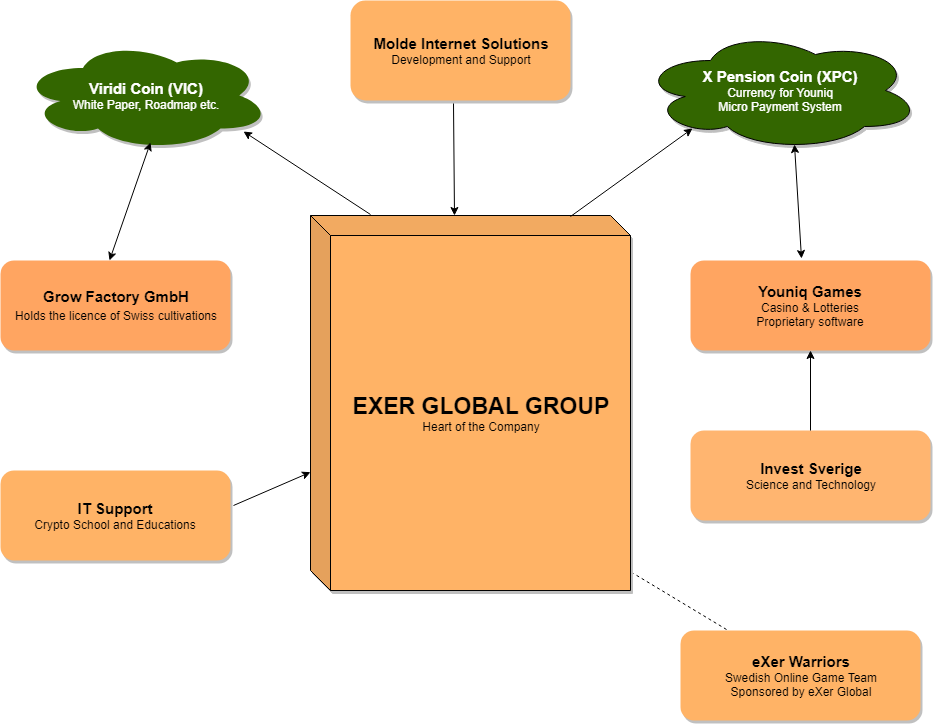

OUR MISSION

MOXY OID has developed the disruptive building material we have all been waiting for — one that saves time, money, and lives.

Trade Secret — sustainable and ultra-high- performance products branded as CERLOS. Our CERLOS products have the following qualities;

Fire-resistant, achieving a Class A fire rating.

Termite, insect, rodent and bird resistant.

Mold resistant.

Water-resistant and all-weather stable, won’t shrink or swell.

It can be cut, machined, drilled, and otherwise worked in the field.

It can be molded to almost any shape in manufacturing.

MOXY OID answers the markets’ demand for innovative and sustainable building materials. The composition and properties of CERLOS products contribute to the higher profitability of MOXY OID while being sustainable and environmentally friendly.

CERLOS can be described as a new, engineered wood product utilizing 100% natural ingredients with no chemical additives, unprecedented aesthetic possibilities, and excellent handling characteristics.

CERLOS products have a unique advantage over competing, traditional products by the unlimited supply/origin of the raw materials used in its manufacturing. Furthermore, the combination of its properties, and the fact that at the end of each cycle use, the product can be recycled (cradle to cradle).

CERLOS was born through our desire to solve four global issues; agricultural/forestry waste, energy shortfall, hazardous building materials and environmentally unsustainable.

Not only do we repurpose agricultural or forestry waste, but it is environmentally friendly in both its manufacturing and application. CERLOS is available at a price point that is equal to or less than its competitive products. This proprietary, brand-new material will fundamentally change the trillion-dollar building materials industry.

VISION

MOXY OID will become a global supplier of sustainable building products, initially accelerating High-Capacity manufacturing operations in North America, followed by Europe, Latin America, and Asia-Pacific.

MOXY OID’s market launch product line will be siding/cladding/fascia, followed by roofing products, and then panel boards, displacing competitive, yet inferior, plywood, oriented strand board (OSB), mediumand high-density fiberboard (MDF/HDF) and other engineered wood, fiber cement, plastic MgO boards, and other composite products including drywall.

MOXY OID’S OBJECTIVES ARE:

Patent applications.

Select a site for establishing a high capacity manufacturing facility in the Pacific Northwest. The site should have rail and road transport access. The facility should be 60,000 to 80,000 square feet with a surrounding area of 10 to 20 acres to accommodate materials in and out. Initially, we prefer to lease the property and buildings.

Using traditional media to market CERLOS products to the building material community.

Use influencer marketing to bring CERLOS products to the attention of home and building owners.

Introduce the CERLOS Certified Representatives program with the intent to create a strong regional and national salesforce that is trained to use and promote CERLOS products.

There are severe ecological and economic problems associated with the existing building materials in terms of their properties, input ingredients that are used to manufacture them, the manufacturing process itself, and their environmental impact.

MOXY OID tackled and solved these problems one by one in the span of 18 years of research and development, with more than $22 million spent. The result is our revolutionary building material CERLOS.

CERLOS products are fire, insects/bird/rodent, rot and mold resistant, water and all-weather stable (will not shrink or swell), or decay or are influenced by environmental hazards. MOXY OID manufactures superior performance, sustainable, energy efficient, and cost-effective building materials that install easily with conventional carpentry tools. MOXY OID’s manufacturing processes are environmentally responsible and petroleum-free, addressing market needs for building “green.” Their products are designed to meet the most stringent testing requirements of the industry and demonstrate superior performance in all key attributes.

CERLOS IS ORGANICALLY CHANGING THE BUILDING MATERIALS INDUSTRY.

Our new construction material to date has been successfully tested in a vast array of different forms of structural and value-added building products.

In each and every case, improvements were made in economics and end-product quality. CERLOS products demonstrate many profound and dramatic characteristic improvements over the products that are currently in use. A product having the improved characteristics of this new technology presents a worldwide opportunity, and to date, no evidence of any other company or research organization proclaims to have discovered anything close to this new material. The ratios of the ingredients within the blends or formulate vary by design according to the required end-product specifications.

These improved characteristics are achieved by a natural, environmental process called Mineralization, which is when organic fiber is strengthened as the porous gaps in the fibers or cells are filled in. This process can occur naturally under certain conditions resulting into petrified wood or fossils and can also occur biologically with the formation of our bones, egg shells, teeth or coral.

CERLOS material can eliminate the need to cut down forests as the input ingredients can be farmed. Remarkably, there are only three, all of them commonly available ingredients used to make CERLOS products. The primary ingredient is lignocellulosic fiber, which is basically every living plant’s fiber. Therefore, the fiber can come from agricultural waste and other organic material sources, even those sources currently considered unusable in the production of building materials. The second ingredient is a commonly available, inexpensive, non-toxic mineral. The mineral is available worldwide and is used in food supplements and so is very eco-friendly. The last ingredient is a commonly available non-toxic liquid. This liquid is used in agricultural applications, is inexpensive, and easily obtained in very large quantities.

CERLOS products are ecologically positive and 100% recyclable.

A NEW STANDARD FOR BUILDING MATERIALS

After over 18 years and US$20 million spent on Research and Development, we have developed a brand new building material that addresses many problems associated with current building materials. CERLOS solves the following issues:

SUSTAINABILITY

Unlike other building materials, CERLOS is created using 100% sustainable methods and can be 100% recycled after use to make brand new CERLOS.

DURABILITY

CERLOS products are fire resistant, insect/bird/rodent resistant, rot and mold resistant, water and all-weather stable (will not shrink or swell), or decay or be influenced from environmental hazards.

ECO-FRIENDLY

Our primary ingredient is lignocellulosic fiber. Lignocellulosic fiber is basically the cells of virtually all living plants, so the fiber can come from straw, cornstalks, or from any other agricultural or forestry waste.

CERLOS CERTIFIED REPRESENTATIVE PROGRAM

Word of mouth recommendations for a brand new product such as CERLOS lends itself best for market acceptance. Although most building owners and homeowners have an idea of what products they would like to integrate on their new home or during renovation, the contractor or builder they have entrusted the construction to normally will influence the materials used. Financially motivated and financially committed builders and contractors are the solution to a successful brand new product distribution in a controlled manner.

MOXY OID has developed an innovative yet proven method of the new product to market through direct sales with the development of its CERLOS Certified Representative program. (CCR). Building materials have traditionally been distributed either from distributors to dealers or directly to dealers, then the dealers price and sell the products to contractors/builders. Contractors are constantly looking for new ways to generate profit without having to charge the building-owner additionally and using CERLOS does just that. A CCR can improve both their and their clients’ quality of life through safer homes and a cleaner environment using a superior product at a lower installed price compared to other standard building materials, all while enjoying increased profit margins.

CCR program is an opportunity for contractors and builders alike to have access to this brand new, high-demand, and limited production proprietary building material for safer homes and a cleaner environment.

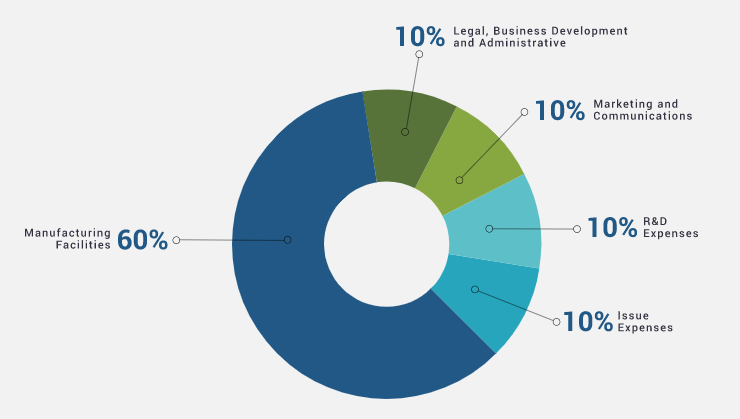

Tokenomics

Why are we holding a token sale?

We have functioning prototypes. CERLOS works. High volume manufacturing process has been validated. Now we need to tell the world! The Token Sale will allow us to scale the CERLOS vision, through covering necessary manufacturing and marketing costs needed to fulfill orders.

Unsold tokens will be retained by the Company as treasury tokens. Just like treasury shares they are not included in the distribution of dividends or the calculation of earnings per token. The Company, through a board resolution, may decide to offer them again for funding at a future date.

Who will qualify to invest?

Qualified investors must undergo a KYC process. Investors from the following countries are not allowed to participate: Malaysia, USA, Canada, Syria, Iran, Iraq, Congo, Libya, North Korea, Somalia, Sudan, Ukraine, Venezuela, Yemen, Zimbabwe, Belarus, Cuba.

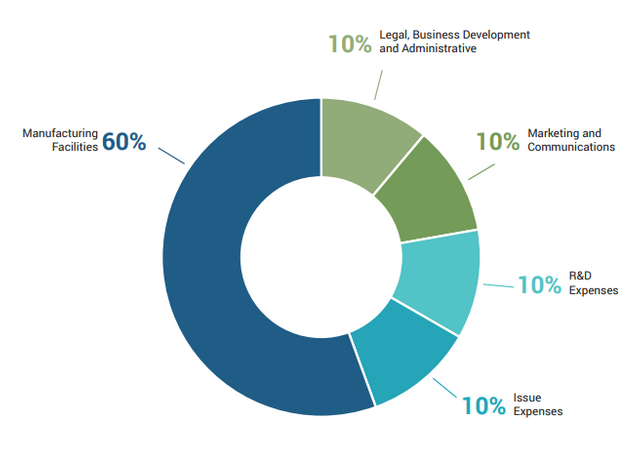

Use of Funds

Roadmap

1985

Alan Heywood (President & CTO) purchased a patent and formed C-Max Technologies International Inc.

1986-2002

Lab research and testing. The IP is developed. $12 million spent on R&D.

2002

C-Max Technologies is dissolved. Alan develops the technology as a sole proprietor.

2003-2008

Alan continues to research, focusing on sources of ingredients and process equipment. Engagement with Corvallis Tool Company of Oregan to design and manufacture a preliminary design. Further $1 Million is spent on R&D.

2010

MOXY OID is established to aid the management and commercialization of the technology. Cost: $2 Million.

2012-2017

Pilot Plant process facility is built in Holland by VDL Enabling Technologies group. High-volume production validated. $7 Million spent.

2018-2019

Preparation and development of websites and documents for funding of high-volume manufacturing facility and legal requirements. Cost is $500k.

March 2020

Pre-Sale Starts

First Quarter 2020

Begin High-Capacity design/build of manufacturing line

Second Quarter 2020

Canada/US Site Selection

Second Quarter 2021

First Employment of High-Capacity of 450 million ft2 per year in North America

For More Information Click Link Bellow:

ETH: 0x4cEaD27a6A2aAEdAa44d35D8BF2a2c9370AbbE6a